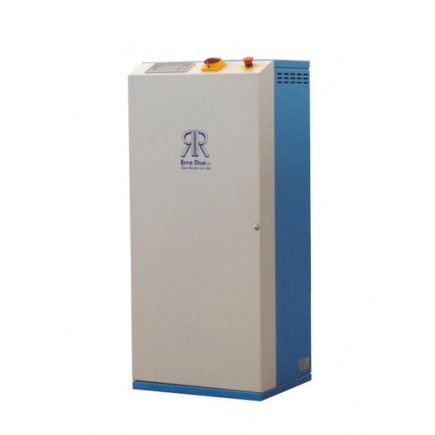

NitroBox is a simple and compact system for producing pressurized nitrogen directly where it is needed, for laser cutting and any other application where pure, compressed nitrogen is needed.

The high purity of nitrogen produced by NitroBox makes it possible to cut stainless steel up to 20mm thick, with a clean, bright cutting edge.

NitroBox has been designed and developed to allow quick and easy installation to immediately obtain an on-site supply of nitrogen at the desired pressure-a true plug-and-play system.

NitroBOX requires only compressed air (already in your plant) and a supply of electricity for the compressor, saving significant time and money.

NitroBOX is immediately ready for use. Thanks to PSA technology, Nitrogen is produced directly from the air, without the use of chemicals. NitroBOX can easily replace high-pressure Nitrogen

cylinders and liquid Nitrogen for laser cutting and other heat treatments.

NitroBOX is capable of autonomously producing the Nitrogen required for cutting by filling the integrated tank at 40bar pressure or cylinders at 200 and 300 bar.

From this tank, Nitrogen is piped directly to the laser system, with flows of up to 500Nm³/day.Storage capacity can be increased simply by adding one or more tanks alongside the NitroBOX system, or cylinder packs.

Advantages of on-site nitrogen production:

- On-site production means no downtime to replace cylinders, no cost for transporting gas, no gas waste due to low residual pressure in cylinders.

- On-site production means consistent gas quality, with no fluctuations due to different gas batches or contamination of the gas in the cylinder.

- On-site production means greater safety for the laser operator, eliminating the need for high-pressure cylinders or liquid nitrogen.

All ErreDue gas generators are available for rental and sale in the Italian territory.